Description:

1.Application:

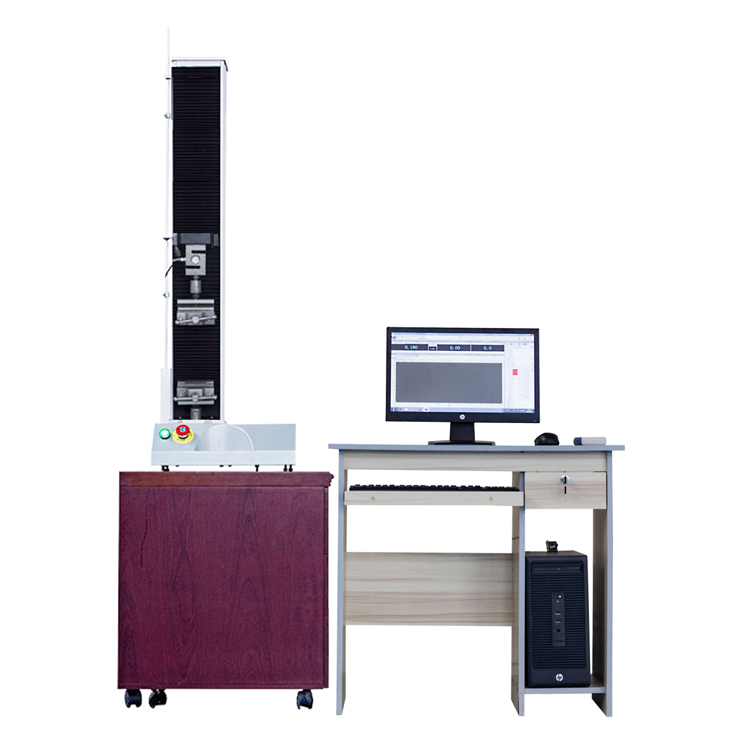

LDW Series (Desktop Type) Single Column Computer Control Electronic Universal Testing Machine uses high

strength light bars to fix the upper beam and the worktable to form a high-rigidity frame structure.

It is driven by servo motor, which drives beam to move up and down through transmission mechanism to

realize the test loading process.

It is mainly used for testing mechanical properties of various metals, nonmetals and composite materials.

After the test is finished, the above test parameters are automatically calculated by microcomputer controller

according to test parameter conditions set at the beginning of the test, and the corresponding test results are

displayed and automatically saved. Each test parameter can be queried and displayed after the test.

It is suitable for manufacturing industries such as metals, adhesives, pipes, profiles, aerospace, wires and cables,

petrochemical industry, waterproof coiled materials, textiles, fibers, rubber, ceramics, food, medical packaging,

geotextiles, films, paper and other manufacturing industries as well as product quality supervision departments

at all levels. It is also suitable for teaching demonstration work in colleges and universities.

2.Technical Parameter:

Model | LDW-01 | LDW-05 | LDW-1 | LDW-2 | LDW-3 | LDW-5 |

Max. Test Force | 100 N | 500 N | 1 KN | 2 KN | 3 KN | 5 KN |

Accuracy | Class 1 |

Measurement Range | 2% ~ 100%FS |

Measurement Accuracy | ±1% |

Test Force Resolution | 1 / 500000 Of Full Scale |

Displacement Measurement Accuracy | ±1% |

Displacement Measurement Resolution | 0.001 mm |

Deformation Measurement Accuracy | ±1% |

Deformation Measurement Resolution | 0.001 mm |

Displacement Control Speed Range | 0.001 ~ 500 mm/min |

Adjustment Range Of Stress and Strain Control Speed Rate | 0.005 ~ 5%FS/S |

Max. Stroke Of Crossbeam | 800 mm |

Effective Tensile Space | 0 ~ 650 mm |

Effective Compression Space | 0 ~ 650 mm |